The limestone quarry of Eigenrieden currently contains a sufficient volume of material at the layers of the lower shell limestone; the Mineral Baustoff GmbH produces annually approx. 220.000 t construction materal mixtures and grit. Facility technology and construction machines were conventionally powered by Diesel, yet. Consequence: The location annually emits an amount of carbon dioxide of approx. 490 t. Up to the end of the running decade this carbon dioxide emissions shall be reduced to almost zero step-by-step by several subprojects. For the decarbonization, the Mineral Baustoff GmbH puts its money on the conversion of conventional Diesel machines on electricity and electrical machines and climate-neutral fuels – Step by step and regarding all three steps of the production process: extraction, processing and loading.

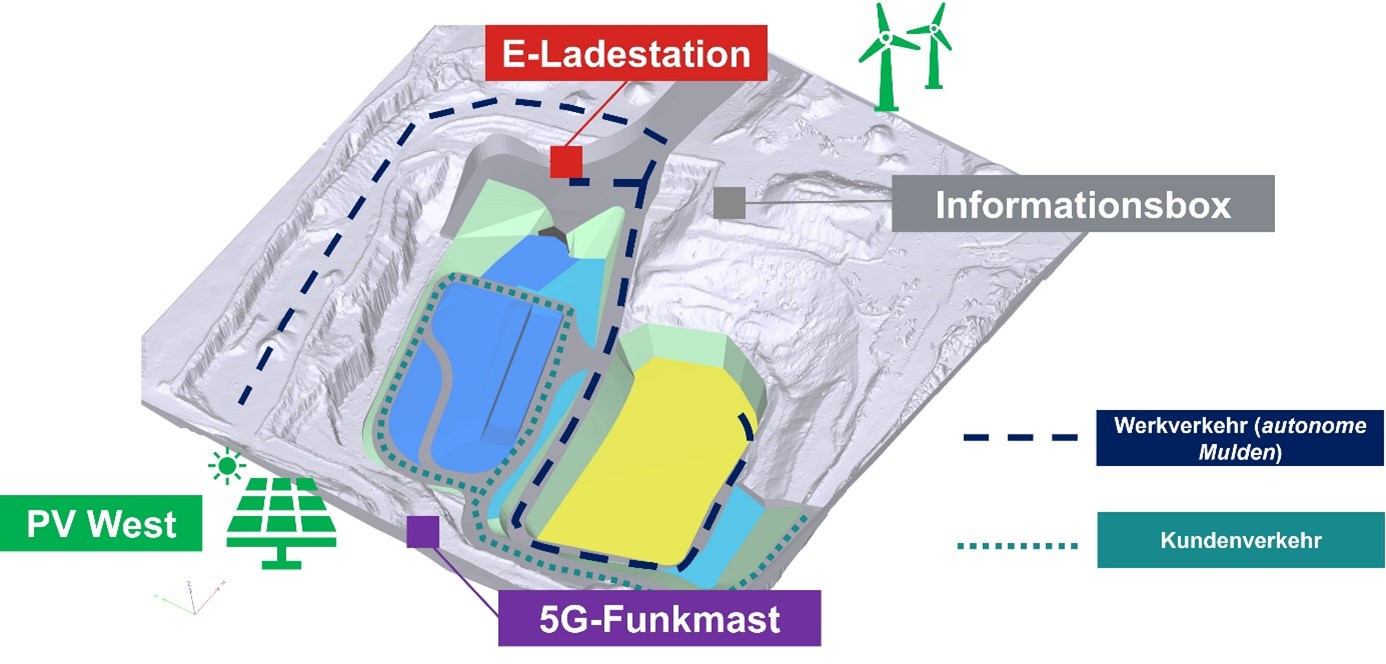

To systematically reduce the CO₂ footprint the MINERAL puts its money in the research of ELMAR especially in the step-by-step introduction of electrical and autonomously powered transport vehicles. The power supply of the electrical transport vehicles is run by a battery accumulator specifically being designed especially for this project with the idea of it being charged via wind and solar power. To network the electrical autonomous transport vehicles with themselves and to digitize the production processes at the quarry, additionally a 5G network is implemented. The start of the trial operation of the first electric and autonomous VOLVO heavy duty transport vehicles is planned on the summer of 2024. In the future, three of this emission-free transport vehicles shall be used in the quarry to carry the extracted limestone to the processing plant. This does not just lower the carbon dioxide footprint but also sustainably improve the work safety and the health protection in raw material extraction. To display the project results there should be implemented an information box at the quarry which gives the opportunity of experiencing the project results under real circumstances to interested people.

The Nivelsteiner Sandwerke und Sandsteinbrüche GmbH is a family operated company in the urban region of Aachen and a strong research partner of the RWTH Aachen University. Within the framework of the Reallabor Nivelstein there exists a perennial cooperation between the AMT and the company. This means the first construction of research and development infrastructure in a raw material extraction company. As an associated partner of the research project the Nivelsteiner Sandwerke und Sandsteinbrüche GmbH make available parts of the Nivelstein factory for realization and demonstration of the electrified intra- and inter-company material transport. Moreover, a private 5G network for the operation of the intra-company electrical-autonomous transport vehicles and a local battery storage for optimizing the energy management are part of the use case.

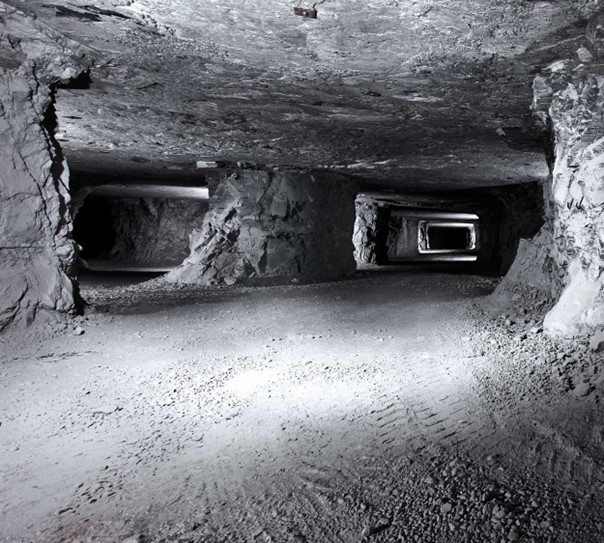

The project Altertheimer Mulde is about a proposition being planned by the Kauf Gips AG to drive up an underground raw material extraction plant to extract gypsum. The start of produce is scheduled at 2026. The feed performance is planned to be 300.000 t/a in the first three years after mining exploration, later, under full load, 1.000.000 t/a shall be produced. The gypsum is produced below ground using the room and pillar process.

This processes are nowadays normally powered by Diesel engines. In further course the gypsum is being fractured and conveyed from the mine to raw material silos at the surface by a conveyor system. From this point the material has to be transported to the 55 km distant gypsum works in Iphofen by truck.

This use case is unique in the syndicate because of the conceptional properties of a Greenfield-Project. Thereby this use case offers the possibility to maintain the necessary processes and infrastructural demands at a very early time in the project. Especially these results can be used in the previous Work Packages to apply the effects of electrified heavy duty transportation on underground work and process structures.

This does not only fulfill the immediate goal of electrifying the intra- and inter-company heavy duty transportation and carbon dioxide reduction, but also reduces the emissions of Diesel engines with respect to the work and health protection in the underground.